Rollester High Quality Lithium Complex Grease

Description

Lithium Complex Grease is a non-leaded, lithium complex, extreme pressure grease, capable of operating at higher temperatures than normal lithium greases. It provides good rust protection, efficient water resistance, excellent stability against oxidation and good resistance to mechanical breakdown.

Benefits

Own excellent high temperature resistance performance, it also can remain on spot at friction pairs under high temperature, and provide continuous protection to bearings and friction pairs, effectively extend service life under high temperature condition

Good EP and anti-wear properties, satisfy lubricating requirements for bearings of heavy load or impact load equipment ·

Excellent oxidation resistant performance, it can ensure longer service life during application ·

Excellent flow character ensures its low temperature pump-ability.

Application

Lithium Complex Grease is suitable for use in centralized lubricating system of rolling mill and rolling bearing in metallurgical industry, it also can be used for lubricating bearings in mine, machinery and transport industry. · Applications where the temperature range is from -20 ℃to + 200 ℃.

Typical Characteristics

|

#2 |

#3 |

|||

|

Characteristics |

Unit |

|

|

Test Method |

|

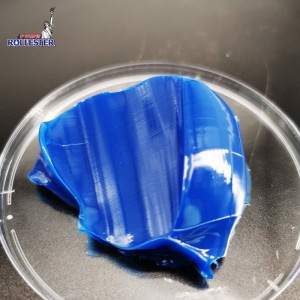

Color |

|

Blue |

Blue |

|

|

Appearance |

|

Smooth |

Smooth |

|

|

NLGI Grade |

|

2 |

3 |

|

|

Soap Type |

|

Lithium Complex |

|

|

|

Base Oil Type |

|

Mineral Oil |

|

|

|

Operating Temperature Range |

°C |

-20 to 200 |

-20 to 200 |

|

|

Dropping point |

°C |

260 |

260 |

ISO2176 |

|

Worked Penetration |

1/10 mm |

265-295 |

220-250 |

ISO 2137 |

|

Kinematic viscosity at 40°C at 100°C |

cSt |

156 14.5 |

156 14.5 |

ISO 3104 |

|

Water washout, 1h at 38°C |

% |

0 |

0 |

ASTM D 1264 |

|

Corrosion prevention, 48h @ 52℃ |

|

Pass |

Pass |

ASTM D 1743 |

|

Oil separation 24h @ 100℃ |

% |

1.2 |

1.2 |

FTMS 791C-321.3 |

|

Four Ball Weld Load |

N |

2560 |

2560 |

IP239 |