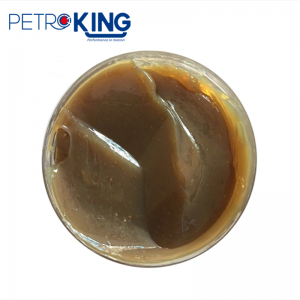

Complex Sulfonate Calcium Grease

Typical Properties

|

Item |

Typical results |

Test Method |

||

|

NLGI Grade |

#1 |

#2 |

#3 |

— |

|

Worked cone penetration, 0.1mm |

310~340 |

265~295 |

220~250 |

GB/T 269 |

|

Dropping Point, ºC Min |

330 |

GB/T 3498 |

||

|

Corrosion, (T2 sheet copper, 100ºC, 24h) |

No green or black change |

GB/T 7326 (Method B) |

||

|

Oil separation by steel mesh, 100ºC, 24h % Loss |

0.7 |

SH/T 0324 |

||

|

Evaporation, (99ºC, 24h) % ≤ |

0.8 |

0.6 |

0.5 |

GB/T 7325 |

|

Water Washout @38ºC,1h, % loss ≤ |

1.0 |

0.8 |

0.5 |

SH/T 0109 |

|

Roll stability ,(28ºC,2h) % Change No adding water |

+4 |

+2 |

2 |

SH/T 0122 |

|

Four-ball test, |

100×9.8 |

GB/T 3142 |

||

Application

It’s intended for :

bearings in contact with water, for example textile and paper making machine that in touch with water for long time;

bearings of hot rolling and calender in steel mill;

bearings under high temperature, for example, Tensile excavator, hot air blower, heat-setting machine, high temperature vat etc;

various industrial equipment like wheel hub bearing of vehicles, heavy load machines, and steering wheels of trailers etc.